More Information

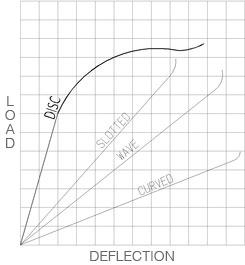

- For maximum load build up with minimum washer deflection compared to a bowed washer. They provide high loads in small spaces.

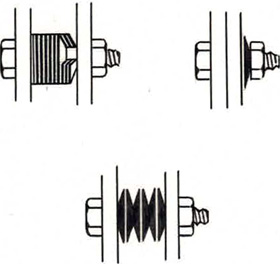

- Stacked in nested multiples disc (Belleville) washers provide extreme load build up.

- Stacked in inverted pairs disc (Belleville) washers provide maximum washer deflection (flexibility) and less load build up.

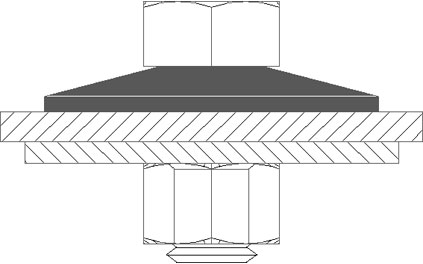

- Used for both dynamic loading as well as static – a typical static application is to take up thermal expansion / contraction on a bolted assembly.

Stock Materials

- Spring Steel: SAE 1074 / ASTM#A684, hardened to Rockwell C45-50.

- Stainless Steel: 301 / 302 Stainless Steel to ASTM#A177.

* These are materials we stock in various thicknesses. It does not mean we have finished inventory of all washers in each of these materials.

** Non stock alternate materials that are commonly run are Phosphor Bronze to ASTM#B103, and 17-7 Stainless Steel.

*** Customer specific materials different than those listed above are commonly run.

Finishes

- Steel: Provided Plain Finish. Disc (Belleville) washers can be provided with a mechanical zinc plating processed in house which eliminates hydrogen embrittlement. A wide range of additional coatings are available: zinc electroplating, phosphate coatings, black oxide, etc.

- Stainless Steel: provided plain finish.

- Phosphor Bronze: provided plain finish.